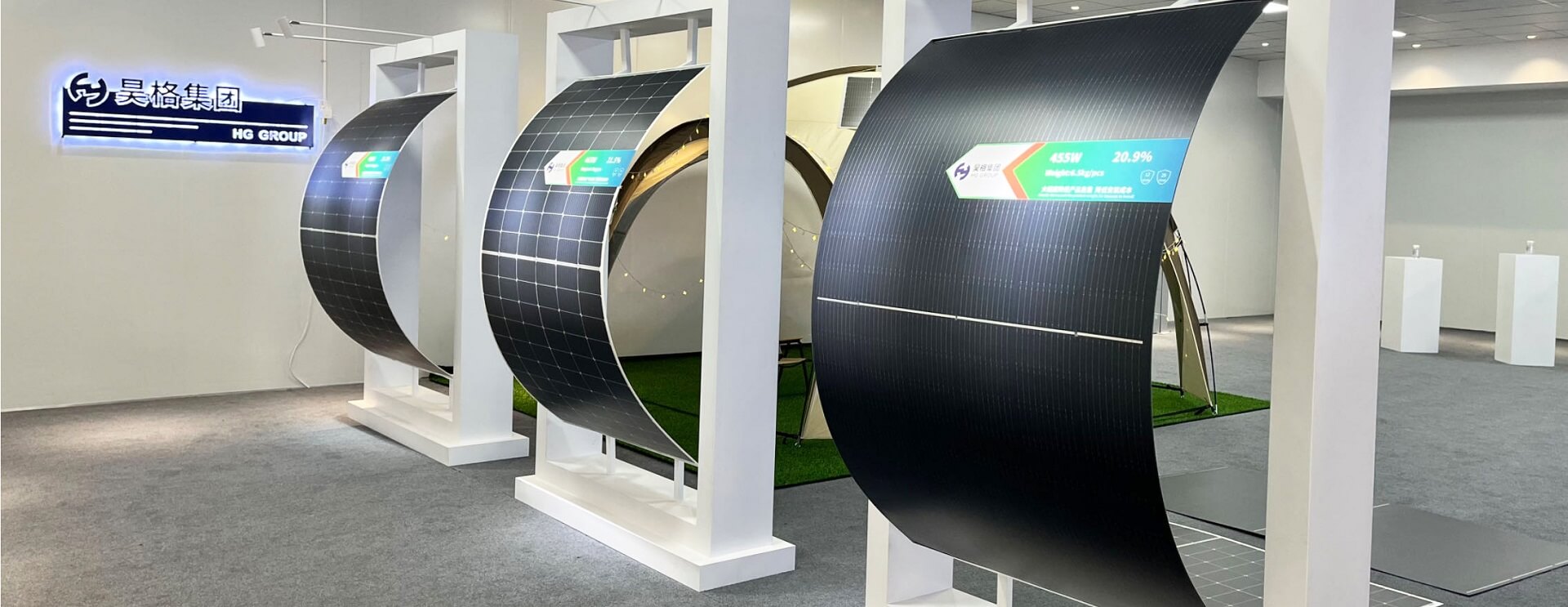

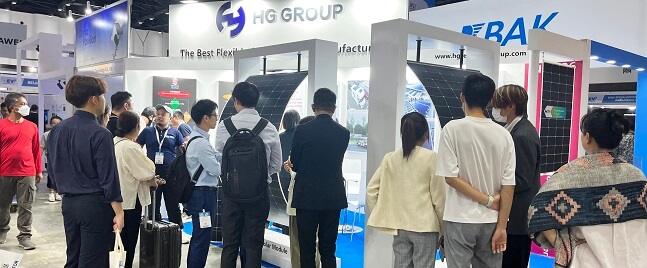

////// Flexible PV Module Mfr

-

Our Businesses

Residential Projects

HG solar modules combine the best features of cell technologies to achieve best performance levels at your service, which ensures HG solar modules achieve maximum luminous efficiency under real, day to day conditions, even under cloudy skies.

Know MoreCommercial Projects

With proven track record of reliability, durability, and cost-effectiveness, HG solar modules provide with over 25 years effective working time; HG solar modules have paved the way for a sustainable and cleaner future for commercial usage.

Know MoreUtility Projects

HG solar module, stand through extreme weather conditions and acid-base climate, due to its incredible durability and intelligent design; HG solar modules are packed with features that have rapidly made them a favorite for solar modules around the globe utility projects.

Know More -

Locations

Welcome to HG Group

You are currently on the HG Group Global Website.

You can come and have a factory inspection visit, we are so gladly to introduce to you our most advanced production line in the world..

Supported by Google Maps

-

Contact Us

Contact Us

Do you have any queries about the products or company?

Please do not hesitate to submit your concern.

Factory Location: Chongqing, China

Your Inquiry (Boxes marked * are mandatory.)

A New Era in Solar Power is Here

Is the bigger the size of the solar flexible module really, the better?

As an effective complement to traditional glass modules, lightweight modules make up for the shortcomings of being light, flexible and bendable. However, it is much more difficult to make flexible solar modules than traditional glass modules.

90% of the flexible solar modules should solve the problem of lightweighting, but there are not many applications in bending scenarios. At present, most of the front panels of flexible modules are made of polymer materials, and their capabilities in terms of water resistance, ultra-low temperature, UV resistance, and impact resistance are issues that have not yet been completely solved. The performance of the glass front panel in water resistance, impact resistance, and ultra-low temperature is much easier and superior.

As the use of flexible solar panels in the market grows, more and more solar module companies are investing in the production of flexible solar panels without hesitation. In fact, more troubles will expose a series of problems within four to five years of module installation and use. Even some product problems will appear two or three years after installation.

1. Let’s talk about the issue of water resistance first. The water resistance of polymer front plate materials is far from being comparable to that of glass. Although manufacturers will give water resistance data, these are static data. As a photovoltaic module, As an important material, the water resistance of polymer front plate materials will decrease year by year when used in real outdoor environments. This is caused by the material characteristics of the front plate material itself and is inevitable. I will not go into details here.

2. Let’s talk about the adhesive film, EVA, EPE, POE. The basic problem is not big when used in glass modules. However, when used in modules encapsulated with polymer materials, the water vapor passing through the front panel, module edge measurement, and adhesive film will It gradually increases over time and causes irreversible performance degradation of the cells.

3. After leaving the factory, transportation conditions and packaging design and production will cause certain damage to flexible solar panels, but the biggest damage is the irreversible cracking of modules caused by workers' grabbing, on-site movement, and installation processes.

4. Another phenomenon that is often ignored by most installation companies is the installation method of modules. Since most flexible solar modules are currently installed with glue, this is a very bad installation method in my opinion. This brings a series of troubles to the future maintenance of the house itself. For the convenience of installation, many companies will glue the modules horizontally on the top of the roof ridge. However, when summer comes, the flexible solar modules will deform due to the characteristics of the material itself, so we often see the modules recessed on the roof ridge. Dust will accumulate above the module, and more severe internal stress in the module will cause cracks in the cells. During many years of on-site inspections, the author found that many roof systems do not receive regular and effective flushing and maintenance. Only when hot spots and breakdown of modules occur will the cause be traced, and the manufacturer of flexible solar modules is often the responsible party.

5. The last important question is, is the bigger the size of the flexible solar module really better? Facts have proved that regardless of traditional modules or flexible solar modules, it is necessary to choose the appropriate module size according to different scenarios, rather than blindly pursuing cost reduction. Oversized components need to be strengthened in addition to their own materials and auxiliary materials.

Flexible modules are mainly used on the top of various distributed buildings. The oversized size will cause cracks in the cells at different levels during manual movement and transportation on site, and will increase a certain degree of difficulty during installation. Due to the light weight of the flexible modules themselves , many times workers will operate alone or even with one hand, which also greatly increases the risk of cell cracks.

At present, many companies are involved in the development of large-sized modules above 520W. Through years of practice and exploration, the author believes that the application of ultra-large-sized flexible solar modules must be treated with caution. From 430W to 520W, the longest side of the module has exceeded 2 meters, close to 2.3 meters, and the short side is also close to 1.2 meters. Perhaps the cost of auxiliary materials saved is not as much as a fraction of the various damages caused by the product after leaving the factory.

Most solar module companies do not have real materials researchers, but more quality management personnel, so they have very strict quality control before solar module leaving the factory. But problems with flexible solar modules often appear after they leave the factory.

Look, maybe in three years there will be more and more quality complaints about flexible solar modules.

Last Updated: March 5th, 2024